Ventilation plastic pipes: features of use

Ventilation plastic pipes are becoming more important in the building materials market today.

And the fact that when laying sewer, water, gas and heat supply systems, the importance of plastic pipes has become decisive is an undeniable fact.

The aesthetic appearance of plastic ventilation pipes is one of the key factors in their use in ventilation systems.

As a rule, such ventilation is built in bars, cafes, gyms, fitness clubs and other places where a mass congestion of people is initially expected.

In addition to their attractive appearance, plastic ventilation pipes meet all sanitary and hygienic requirements, and the reliability of plastic ventilation structures is not in doubt, since the highly tight connections of such pipes do not allow any leakage.

Scopes of plastic ventilation pipes

Plastic ventilation in everyday life

In the installation of household ventilation, structures and pipes made of galvanized iron were previously used. However, plastic products over the years, for sure, will displace obsolete materials from the pedestal.

To date, plastic ventilation pipes are produced in the following types:

- polyvinyl chloride (PVC);

- polyurethane;

- polypropylene.

Of these materials, the most commonly used are those of a medium or light type. They are absolutely harmless to people, resistant to UV radiation, completely sealed, easy to install and maintain in terms of hygienic cleaning.

Plastic ventilation pipes cannot withstand temperatures close to the melting point of the material.

It is because of this that ventilation systems for saunas and baths are still mounted from metal.

Industrial plastic ventilation

In any industrial production of many industries, plastic pipes for ventilation are widely used. Even at the stage of designing ventilation systems at industrial enterprises, all the features of the technological process and all its stages are taken into account.

In those rooms where the temperature can take critical values for plastic (80 degrees and above), plastic ventilation pipes are not subject to installation. But in this case, the option of an external ventilation system passing in the open air outside the heated room can be considered.

Advantages and disadvantages of plastic air ducts

Advantages of plastic air ducts

The main advantages of plastic air ducts, which are difficult to dispute, are their physical properties, namely lightness, strength and, therefore, ease of transportation. Therefore, many engineers of ventilation systems give their preference to galvanized air ducts.

Full list of benefits:

The above mentioned properties will save on the maintenance of all ventilation equipment.

- Installation of plastic air ducts is very simple compared to metal. Plastic pipes can be cut and adjusted in size right at the ventilation installation site.

- An important advantage is the absolute safety of plastic pipes for the human body., as well as the absence of any harmful emissions and emissions into the environment.

Disadvantages of plastic ducts

As usual, each medal has its reverse side. In this sense, plastic air ducts will not be an exception.

The main and most significant drawback endowed with a plastic ventilation pipe is low resistance to fire.

This is in many cases the decisive argument in favor of metal air ducts. This circumstance greatly limits the scope of plastic air ducts, and forces ventilation system engineers to use plastic air ducts only within one fire zone, department or compartment.

The low level of fire protection that a plastic ventilation pipe has cannot allow the use of such air ducts for the installation of industrial ventilation, which involves its passage through a number of fire hazardous departments.

As a result of the foregoing, it is recommended to use plastic air ducts exclusively in the installation of a ventilation system that will serve a local room or several such rooms belonging to the same fire zone with a temperature acceptable for plastic.

Features of installation of plastic ventilation

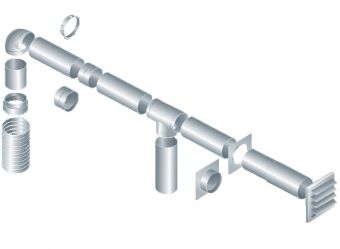

As a rule, for the installation of a ventilation system, in which one of the constituent elements is a plastic pipe for ventilation, a metal pipe (160 mm) is constructed directly at the outlet of the system, equipped with several branches for ventilation pipelines.

In some cases, the systems are equipped with blower or suction fans, which provide a quick forced draft of air.

Pipes with a larger diameter (225 mm) can be used in some critical situations when it is necessary to take into account any architectural features of a building or a particular room. There may be some engineering problems here.

Preference for plastic ventilation pipes today is given not as a tribute to fashion, but due to more attractive characteristics in almost all respects. As in other communication systems, where plastic has taken a leading position, in the field of ventilation, a change in priorities will probably not be long in coming either.